Proper preparation with specialized tools and safety gear is crucial for a Tesla HV battery inspection. This includes diagnostic equipment and protective wear. A car body shop equipped to handle high-voltage batteries performs these inspections, identifying damage or issues that could affect performance and safety. The initial step involves a meticulous visual examination for signs of physical damage or corrosion. Comprehensive functional tests measure key metrics like voltage, current capacity, and resistance to ensure optimal battery health and performance, especially after significant repairs.

“Uncover the secrets of a Tesla HV battery’s health with this comprehensive step-by-step guide. Before diving into complex diagnostics, proper preparation is key. Equip yourself with specialized tools and safety gear for a thorough inspection. From visual assessments to functional tests, each step reveals critical insights. Learn to examine components, connections, and overall performance. Master the art of Tesla HV battery inspections and ensure optimal electric vehicle health.”

- Prepare for Battery Inspection: Gather Tools and Safety Gear

- Visual Inspection: Examine Battery Components and Connections

- Perform Functional Tests: Assess Battery Performance and Health

Prepare for Battery Inspection: Gather Tools and Safety Gear

Before beginning any Tesla HV battery inspection, ensuring you’re prepared is paramount to accurate and safe evaluation. This involves gathering specific tools designed for electric vehicle (EV) diagnostics and wearing appropriate safety gear. For a Tesla HV battery inspection, a comprehensive set of tools will include voltmeters, ohm meters, multimeters, and specialized EV diagnostic scanners capable of reading complex electrical systems. Additionally, a variety of protective wear such as insulated gloves, safety goggles, and an apron is essential to safeguard against potential hazards associated with high-voltage batteries.

A car body shop equipped with the right tools and trained personnel can effectively conduct Tesla HV battery inspections. This process is crucial for identifying any damage or issues that may have occurred due to hail damage repair or other vehicle bodywork incidents, which could impact the battery’s performance and safety. By prioritizing preparation, both in terms of tools and personal protective equipment (PPE), you’re setting the stage for a thorough inspection, ultimately contributing to enhanced EV safety and reliability.

Visual Inspection: Examine Battery Components and Connections

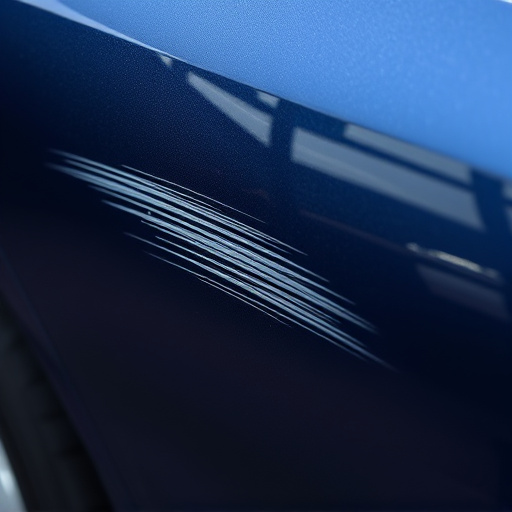

During a Tesla HV battery inspection, the visual examination is a critical first step. Carefully inspect all battery components for any signs of damage, corrosion, or loose connections. Look for visible dents, cracks, or leaks in the battery casing, as well as frayed or damaged wires. Even minor damage can compromise the integrity of the system, so thoroughness is key.

Focus on the battery cells, modules, and the overall wiring harness. Ensure that all components are securely fastened and properly seated. Check for correct alignment and tension of connectors and terminals. This initial visual assessment helps identify potential issues that may require further investigation, such as those that might be more subtle and need professional attention, akin to a collision repair center handling auto glass replacement or vehicle dent repair.

Perform Functional Tests: Assess Battery Performance and Health

During a Tesla HV battery inspection, performing functional tests is paramount to assessing the battery’s performance and health accurately. This involves checking key metrics such as voltage levels, current capacity, and resistance values. By utilizing specialized equipment, technicians can simulate various conditions to ensure the battery functions optimally and safely. For instance, charging and discharging cycles at different rates help identify any anomalies or degradation in battery efficiency.

These tests go beyond basic diagnostics by scrutinizing the battery’s ability to hold charge, discharge power consistently, and maintain stable voltage during operation. In the context of car restoration or auto body services involving significant repairs like dent repair, a thorough Tesla HV battery inspection is crucial. It guarantees that the restored vehicle not only drives efficiently but also offers reliable performance, ensuring safety and peace of mind for drivers.

A thorough understanding of the Tesla HV battery inspection process is vital for ensuring optimal vehicle performance and safety. By following these structured steps, from gathering essential tools to functional testing, you can thoroughly evaluate the health and functionality of your Tesla’s high-voltage battery system. Regular inspections are key to maintaining peak efficiency, preventing potential issues, and extending the lifespan of this critical component in electric vehicles.